Custom mold bases

label

DESCRIBE

- High-quality mold base saves you time and money.

- Material as required or according to our program.

- Non-standard size customization.

- The project manager follows up on the whole process and reports the progress at any time.

Mold base

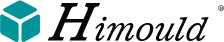

Our bases are completely machined and ready for mold and tool makers for final assembly. We specialize in complex pockets for cores, cavities, slides, and precision boring for round components. Himould offers rough contour machining services of parting line surfaces as well as larger cross-sectional cavities and core blocks.

| Material | S50C/40#/P20/S132/customization |

|---|---|

| Surface treatment | Matte/Common polishing/Mirror polishing/Texture plating |

| Processing service | Molding/Cutting/Polishing/CNC machining service |

| Standard | DIN/AISI/JIS |

| Coolings | Clean and seal according to customer requirements |

| Quality system | 100% inspection before shipment |

| Packing | Wooden boxed/As per customer's specific requirements |

| Plastic parts material | ABS/PVC/PP/PE/PMMA/Acrylic/Nylon etc.. |

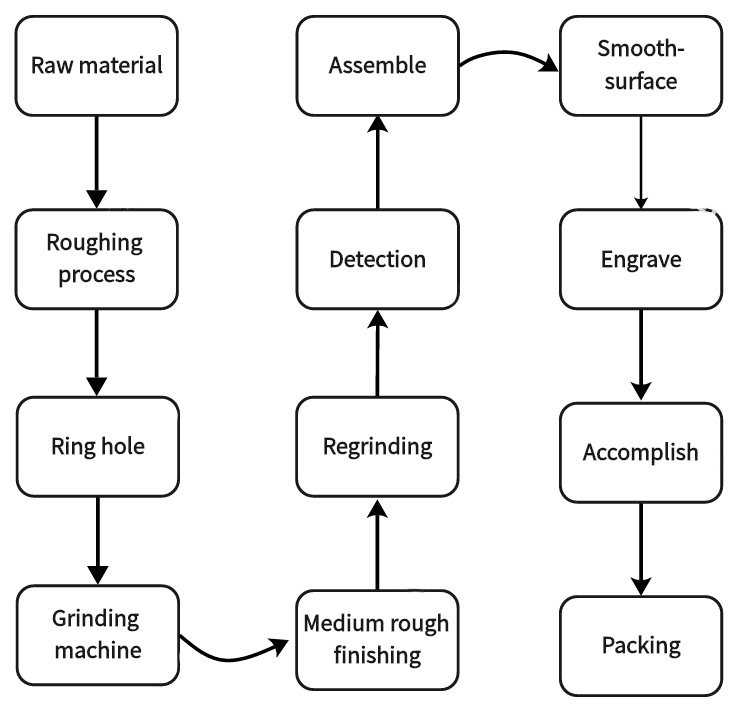

Three-dimensional detection

FAQ

How can you ensure the quality?

We have QC department to control the quality from the begining of production until goods finish.

Can you accept customize?

Yes, It can be customized as per the customers' request.

What's your product range?

Our product range includes various kinds of mold standard parts and mold Component,For example: mold, core, cavity, mold and insert.

When can I get the price of plastic mould parts?

We usually quote within 24 hours after we get your inquiry.If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority"

Related Product